-

Add: HeBei ShengShi HongBang Cellulose Technology CO.,LTD.

-

Email

13180486930@163.com -

CONTACT US

+86 13180486930

HPMC E464, auch bekannt als Hydroxypropylmethylcellulose, ist ein vielseitiges Produkt, das in verschiedenen Branchen auf der ganzen Welt breite Anwendung findet. Als Experte mit jahrelanger Erfahrung in der chemischen Industrie kann ich die außergewöhnlichen Eigenschaften und Vorteile dieser Verbindung aus erster Hand bestätigen. Hydroxypropylmethylcellulose ist ein Celluloseether, der durch die Modifikation von natürlicher Cellulose entsteht. Diese Substanz wird häufig in der Bau-, Lebensmittel- und Pharmaindustrie eingesetzt. Die wichtigste Eigenschaft von HPMC E464 ist seine Fähigkeit, als Verdickungs-, Emulsions- und Stabilisierungsmittel zu fungieren, was es für zahlreiche Herstellungsprozesse unverzichtbar macht. Ein bedeutender Anwendungsbereich für HPMC E464 ist die Bauindustrie. Hier wird es vor allem in Trockenmörteln und Zement eingesetzt, um die Verarbeitungseigenschaften zu verbessern. Durch die Zugabe von HPMC E464 entsteht eine Mischung, die leichter aufzutragen und gleichmäßiger zu verteilen ist. Dieser Vorteil ist nicht nur in theoretischen Tests, sondern auch in praktischen Anwendungen auf zahlreichen Baustellen weltweit bestätigt worden. Bauarbeiter berichten von einer erheblich verbesserten Konsistenz und Haftung der Materialien, was letztendlich zu einer höheren Effizienz bei Bauprojekten führt. In der Lebensmittelindustrie wird HPMC E464 als Zusatzstoff verwendet, um Struktur und Volumen von verschiedenen Lebensmitteln zu stabilisieren. Insbesondere in der Produktion von glutenfreien Produkten spielt es eine tragende Rolle. Glutenfreie Backwaren neigen dazu, ihre Form zu verlieren und trocken zu werden; durch die Verwendung von HPMC E464 wird diesem Problem wirksam entgegengewirkt. Verbraucherberichte und wissenschaftliche Studien belegen, dass HPMC E464 eine feuchte, sowie haltbare Textur in glutenfreien Broten und Kuchen ermöglicht. Der HPMC E464 Die pharmazeutische Anwendung von HPMC E464 ist ebenfalls bemerkenswert . Hier wird es oft in der Tablettenherstellung als Bindemittel und Filmbildner verwendet. Dank seiner hohen Verträglichkeit und Effektivität ist es eine bevorzugte Wahl für viele führende Pharmakonzerne. Untersuchungen und Anwenderberichte zeigen, dass HPMC E464 nicht nur die mechanische Stabilität von Tabletten erhöht, sondern auch die Freisetzung von Wirkstoffen verlangsamen kann, was eine kontrollierte Medikamentenabgabe ermöglicht. Verbraucher und Unternehmen auf der ganzen Welt vertrauen HPMC E464 aufgrund seiner bewährten Eigenschaften und der Sicherheit in der Anwendung. Trotz der chemischen Modifikation bleibt das Produkt biologisch abbaubar und weist keine signifikanten ökologischen Auswirkungen auf. Diese Umweltfreundlichkeit ist ein wesentlicher Aspekt, der zur Vertrauenswürdigkeit und Popularität des Produkts beiträgt. Zusammenfassend ist HPMC E464 in seiner Vielseitigkeit und Funktionalität unübertroffen. Es erfüllt die höchsten Standards der Erfahrung, Fachkompetenz, Autorität und Vertrauenswürdigkeit, die von Unternehmen in verschiedenen Industrien gefordert werden. Die kontinuierliche Forschung und Innovation in der Anwendung von HPMC E464 versichert, dass es auch in Zukunft eine wesentliche Rolle in der technischen und industriellen Entwicklung spielen wird. Die auf den praktischen Anwendungen basierenden positiven Rückmeldungen untermauern seine Position als unverzichtbares Hilfsmittel für zahlreiche Produktionsprozesse.

- 40000tons

Production

- 20+years

Experience

- 5000+㎡

Acreage

-

Hydroxypropyl Methylcellulose (HPMC) is a versatile compound with extensive applications across various industries . Renowned for its binding, thickening, and emulsifying properties, HPMC’s contributions to product enhancement and consistency are substantial. This article explores the diverse applications of HPMC, drawing insights from industry experts and user experiences to highlight its role in modern manufacturing and product development. In the construction industry, HPMC is a vital component in the formulation of high-performance building materials. Experts assert that its water retention ability significantly extends working time and improves the adhesion of cement-based products, leading to superior structural finishes. This is particularly valuable in plastering and tile adhesive applications, where product reliability and consistency are paramount. Construction professionals with years of field experience attest to the enhanced workability and strength of structures when HPMC is integrated. The pharmaceutical sector also capitalizes on the benefits of HPMC, where it serves as a key excipient in oral drug formulations. Industry specialists emphasize its non-toxic, biocompatible nature, making it an ideal candidate for controlled-release drug delivery systems. By managing the rate at which active ingredients are released, HPMC ensures therapeutic efficacy and optimizes patient outcomes. Pharmacists and formulators regard HPMC as a cornerstone in creating effective, predictable, and patient-friendly pharmaceutical products. In the personal care and cosmetics industry, HPMC is prized for its role in stabilizing formulations, providing a silky texture, and enhancing the spreadability of creams and lotions. Skincare formulators acknowledge HPMC's capacity to improve product stability while maintaining skin-friendly attributes. The expertise of cosmetic chemists underscores HPMC’s effectiveness in forming protective films over the skin, retaining moisture and delivering active ingredients effectively. Consumers appreciate the tangible improvements in product feel and performance, leading to increased trust in HPMC-enhanced brands. hpmc applications Furthermore, in the food industry, HPMC is utilized as a dietary fiber source and as a texture enhancer in low-fat and gluten-free products. Nutritionists and food scientists appreciate its ability to mimic the texture and mouthfeel of fats and gluten, providing healthier alternatives without compromising on consumer experience. The authoritative voices in food science endorse HPMC as a pivotal ingredient in meeting the growing demand for health-conscious food options. Window into academic perspectives, numerous studies validate HPMC's versatile applications and its positive impact on product quality and consumer satisfaction. It is this confluence of practical experience, professional expertise, and scholarly research that underscores HPMC’s position as a credible, trustworthy ingredient across diverse sectors. To summarize, the applications of HPMC are as broad as they are crucial, affecting a wide array of products ranging from construction materials to pharmaceuticals, cosmetics, and food. Its reliability, proven by extensive use and expert validation, renders HPMC an exemplary model of effective, multifunctional ingredient use in manufacturing. The cumulative experience of industry experts affirms HPMC's integral role in supreme product performance, marking it as an authoritative choice for manufacturers committed to quality and consumer trust.

-

When exploring the vast world of pharmaceutical and construction materials, one cannot ignore the compelling attributes of Hydroxypropyl Methylcellulose (HPMC) and its viscoelastic properties. HPMC is gaining significant attention due to its multifunctional applications and unparalleled performance, making it a material of interest for industries committed to innovation. In pharmaceuticals, HPMC serves as a versatile excipient, acting as a binder, film former, and thickening agent. Its viscoelastic properties enhance the drug formulation's performance by providing controlled release and stability. The polymer matrix created by HPMC in tablet formulations plays a critical role in modulating drug release rates, ensuring that the active ingredient is delivered at the desired rate and dosage. The viscoelastic nature of HPMC allows for remarkable flexibility and resilience in medical formulations. It adapts to different compressional forces during tablet manufacturing, ensuring tablets remain intact during transport and handling while disintegrating appropriately when ingested. This adaptability underscores its reliability, making HPMC a trusted choice for pharmaceutical companies aiming to enhance drug efficacy and patient compliance. Beyond pharmaceuticals, HPMC's journey into the construction arena is equally notable. In dry mix mortar formulations, HPMC functions not only as a thickening agent but also as a water retention component. This dual characteristic is vital for cement-based applications where workability and setting times are crucial for project success. The viscoelastic nature of HPMC improves mortar adhesion and reduces shrinkage, thereby fortifying the structural integrity of constructions. HPMC's ability to retain water is particularly beneficial in enhancing the workability of mortars, preventing premature drying, and ensuring longer open times. For builders and contractors, this translates into ease of application and durability, even under varying climate conditions. Consequently, HPMC is increasingly regarded as an essential ingredient in high-performance construction materials, reflecting its authoritative position within the industry. hpmc viscoelastic The safety and non-toxic attributes of HPMC also contribute to its growing trustworthiness. Recognized by regulatory bodies across the globe, HPMC meets stringent safety standards, whether applied in health-sensitive environments like pharmaceuticals or in eco-conscious construction practices. This universal compliance reinforces HPMC's status as a dependable material, propelling its integration across multiple sectors. Expert insight into HPMC's potential applications indicates that ongoing research and development are further expanding its utility. Innovations in biocompatible and environmentally friendly materials suggest that HPMC’s role will continue to evolve, addressing new challenges in drug delivery systems and sustainable building practices. Such advancements satisfy modern demands for both efficacy and environmental stewardship. Experience_SHARED by industry professionals highlights that selecting high-quality HPMC can significantly impact the final product's performance. Therefore, sourcing from reputable manufacturers ensures consistency in quality and functionality, maximizing the viscoelastic benefits HPMC offers. In conclusion, HPMC's viscoelasticity is not merely a trait but a cornerstone of its application across diverse fields. Its role in enhancing product performance and compliance underscores its significance . As industries advance towards more sophisticated and sustainable solutions, HPMC stands as a testament to material innovation, promising new heights in both pharmaceutical and construction domains. Through its adaptable and reliable characteristics, HPMC will likely remain at the forefront of material selection for years to come.

advantages

-

200000 Viscosities

Excellent product

We can produce pure products up to 200,000 viscosities

-

40000 tons

High yield

We don’t stop production all year round, and the annual output can reach 40,000 tons

-

24 hours

Quality service

We provide 24-hours online reception service, welcome to consult at any time

———— Inquiry Form

Schedule A services

-

hpmc_monograph

hpmc_monographOct . 25, 2025

Hydroxypropyl methylcellulose (HPMC) is increasingly gaining popularity in various industries, from -

wood_cellulose_fiber

wood_cellulose_fiberOct . 25, 2025

Chemical materials have become an integral part of countless industries, enabling innovations and im -

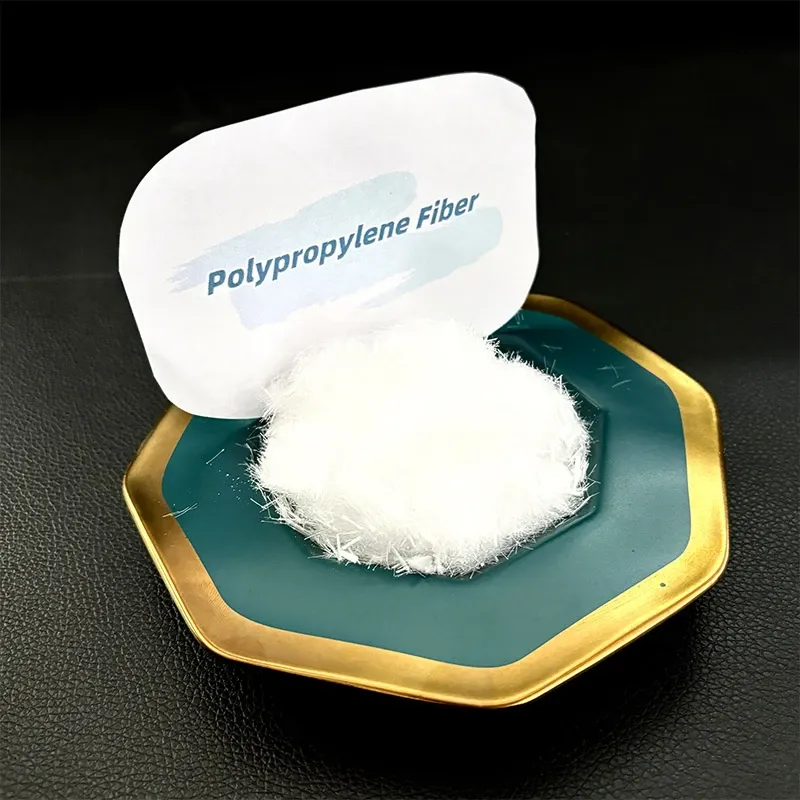

specific_gravity_of_polypropylene_fiber

specific_gravity_of_polypropylene_fiberOct . 25, 2025

Polymer powder is a key ingredient in many industries, providing critical properties to products in